Funding: ESAform benchmark series

Timeline: 10/2025 - 10/2026

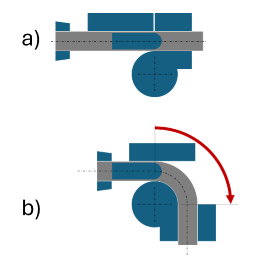

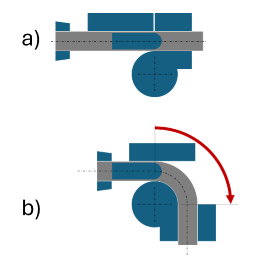

The industrial tube bending process rotary draw bending (RDB) is considered for bending of a high-strength tube at a narrow bending radius. The benchmark committee conducts all material characterization methods to allow material parameterization of the profile. Starting in February 2026, the benchmark participants, i.e., you, are asked to model the bending process with a method and software of your own choice as well as the material with different modeling complexity. In parallel, our committee is conducting the practical experiments (“blind approach”). Before the upcoming ESAFORM 2026 conference, we will compare the modelling and practical results together with you aiming at a detailed presentation of the first results at the upcoming 2026 ESAFORM conference Ultimately, the final aim of the ESAbend26 benchmark project is to provide guidelines that help companies and research centers in selecting the most fundamental tests and models to predict accurate results in profile bending.

Rotary draw bending is a complex metal forming process because of its high number of specific tools, it´s dependence on process kinematics and parameters as well as the influence of the bending machine. Consequently, the process is challenging to model by means of process knowledge as well as for numerical constraints. At the same time, high-strength steel materials have become more common in high-performance industrial applications such as automotive and aerospace. As in the case of dual phase steels, these materials might necessitate more complex material modeling to meet the desired, accurate prediction quality of production engineering (e.g. to layout required process forces and resulting elastic springback of the bent product). Amongst the vast material testing approaches to satisfy the modeling of specific material behavior phenomena, it has been challenging to decide on the most essential tests to achieve the most crucial improvements in modeling prediction quality. In addition to that, circular profiles such as tubes cannot be characterized in standard testing routines due to their cylindrical hull.

The ESAform benchmark series tackles actual, relevant challenges in modeling of metal forming processes. Organized by well-recognized experts in the field, the organizing committee gathers international scientists as participants – i.e., you! – to address and solve the proposed metal forming problem in a community approach. The benchmark team inherently builds up a fruitful network exceeding the exclusive boundaries of the benchmark. Firsthand, you will benefit from our discussions and detailed results. Ultimately, the results will be published in a mutually authored journal paper where the benchmark participants are encouraged to engage. The previous ESAFORM benchmark papers have caught highest attention and impact (LINK).

We are looking for participants from academia and industry out of the domain of production engineering to model the proposed manufacturing problem. Upon your tentative interest, please get in touch with Peter for questions, comments and, most importantly, your participation.

Peter.Frohn[at]uni-siegen.de

Funding: ESAform benchmark series

Timeline: 10/2025 - 10/2026

The industrial tube bending process rotary draw bending (RDB) is considered for bending of a high-strength tube at a narrow bending radius. The benchmark committee conducts all material characterization methods to allow material parameterization of the profile. Starting in February 2026, the benchmark participants, i.e., you, are asked to model the bending process with a method and software of your own choice as well as the material with different modeling complexity. In parallel, our committee is conducting the practical experiments (“blind approach”). Before the upcoming ESAFORM 2026 conference, we will compare the modelling and practical results together with you aiming at a detailed presentation of the first results at the upcoming 2026 ESAFORM conference Ultimately, the final aim of the ESAbend26 benchmark project is to provide guidelines that help companies and research centers in selecting the most fundamental tests and models to predict accurate results in profile bending.

Rotary draw bending is a complex metal forming process because of its high number of specific tools, it´s dependence on process kinematics and parameters as well as the influence of the bending machine. Consequently, the process is challenging to model by means of process knowledge as well as for numerical constraints. At the same time, high-strength steel materials have become more common in high-performance industrial applications such as automotive and aerospace. As in the case of dual phase steels, these materials might necessitate more complex material modeling to meet the desired, accurate prediction quality of production engineering (e.g. to layout required process forces and resulting elastic springback of the bent product). Amongst the vast material testing approaches to satisfy the modeling of specific material behavior phenomena, it has been challenging to decide on the most essential tests to achieve the most crucial improvements in modeling prediction quality. In addition to that, circular profiles such as tubes cannot be characterized in standard testing routines due to their cylindrical hull.

The ESAform benchmark series tackles actual, relevant challenges in modeling of metal forming processes. Organized by well-recognized experts in the field, the organizing committee gathers international scientists as participants – i.e., you! – to address and solve the proposed metal forming problem in a community approach. The benchmark team inherently builds up a fruitful network exceeding the exclusive boundaries of the benchmark. Firsthand, you will benefit from our discussions and detailed results. Ultimately, the results will be published in a mutually authored journal paper where the benchmark participants are encouraged to engage. The previous ESAFORM benchmark papers have caught highest attention and impact (LINK).

We are looking for participants from academia and industry out of the domain of production engineering to model the proposed manufacturing problem. Upon your tentative interest, please get in touch with Peter for questions, comments and, most importantly, your participation.

Peter.Frohn[at]uni-siegen.de